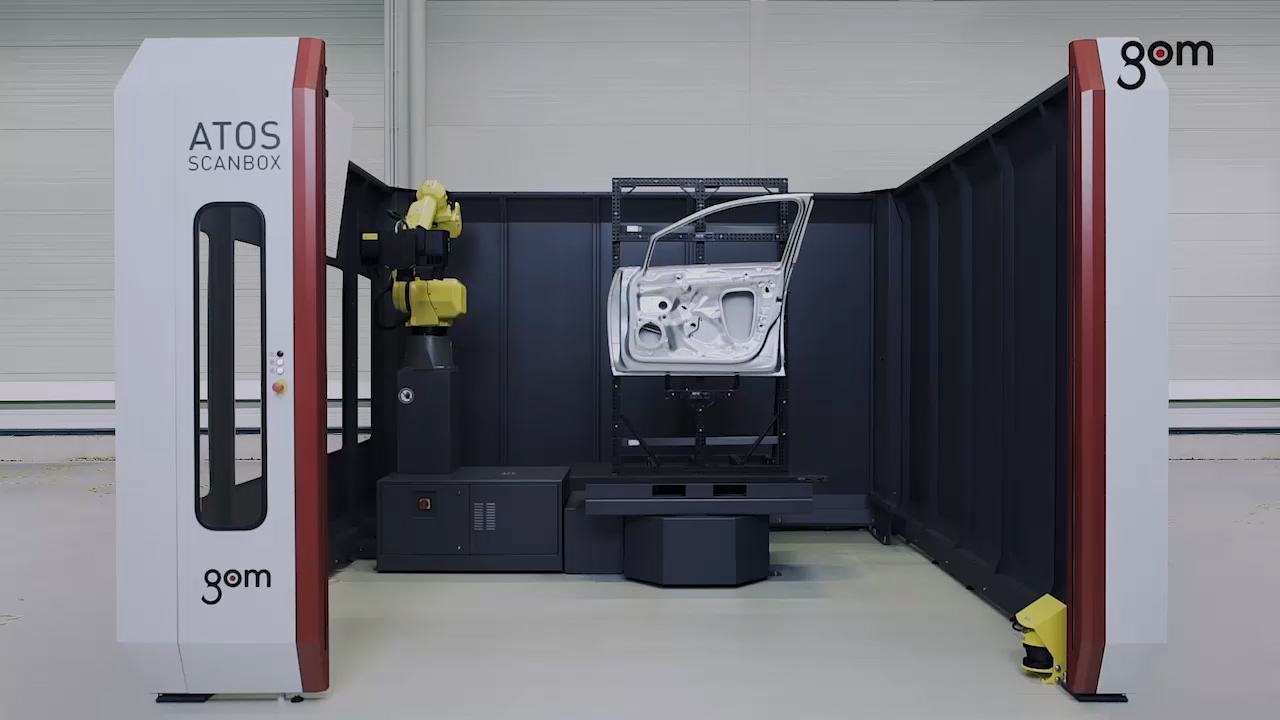

ATOs ScanBox Series 6

Measurement of Parts up to 3000 mm in Size in Production Environment

In production metrology, it is important to identify, analyze and correct quality problems as fast as possible. Many parts are to be checked as completely as possible in order to be able to initiate corrective measures and minimize scrap at short notice and in a targeted manner.

| ATOS ScanBox 6130 | |

|---|---|

| Dimensions | 4250 × 4250 × 2700 mm³ |

| Power supply | 200–500 V (3-phase, 16 A) |

| Max. part size | Ø 3000 mm |

| Max. part weight | 2000 kg |

| Entry | Safety light sensor |

| Opening width | 3100 mm |

| Floor mounting or fixing | Required |

| Loading concept | Manual, transport cart, pallet truck, crane, forklift truck |

| Sensor compatibility | ATOS Capsule, ATOS Triple Scan, ATOS 5 |

For further information about the ATOS ScanBox, please download the brochure.

A typical application for the ATOS ScanBox 6130 is quality assurance in production, for example, of attached parts or interior parts, but also product development and tool try-out.

Measuring 3.1 m, the entrance area of the ATOS ScanBox 6130 is very wide and is secured by a safety light sensor. This allows an uncomplicated use of loading tools, such as cranes, forklift trucks or pallet trucks, in order to be able to place large parts on the measuring machine.

The components and the fixtures can be set up outside of the ATOS ScanBox on changing pallets. The pallets are loaded quickly and reproducibly using positioning pins. This results in a high throughput of parts and is ideally suited for series production.

The virtual measuring room is the central control station and measurement planning software for all elements of the ATOS measuring cells. It offers the functional representation of a real measurement environment in a virtual simulation. Thanks to the VMR, the user can work with the system without requiring specific robot programming skills. All robot movements are simulated and checked for safety before being performed in the actual environment.

UCS Tower, plaza # 1, Hill Road Commercial area , phase 6 , Bahria Town, Islamabad Pakistan

The Pakistans leading 3D Printing Service & Marketplace!