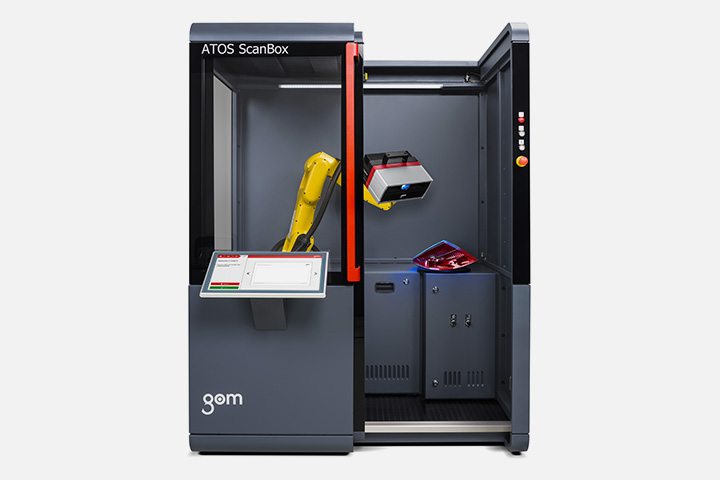

ATOS ScanBox Series 4

Measurement of Small Complex Components up to 500 mm in Size

Injection-molded parts and die-cast components as well as tools, molds, stamping and bending parts often show complex contours and connection geometries which have to be checked during series and batch production ramp-up.

The ATOS ScanBox 4105 is an efficient 3D measuring machine for these applications.

| ATOS ScanBox 4105 | |

|---|---|

| Dimensions | 1600 × 1200 × 2100 mm³ |

| Power supply | Standard, 100 – 240 V (1-phase, 16 A) |

| Max. part size | Ø 500 mm |

| Max. part weight | 100 kg |

| Entry | Sliding door with safety lock |

| Opening width | 685 mm |

| Floor mounting or fixing | Not required, mobile |

| Loading concept | Manual, crane |

| Sensor compatibility | ATOS Core, ATOS Capsule |

For further information about the ATOS ScanBox, please download the brochure.

All ATOS ScanBox models are characterized by their compact design. The ATOS ScanBox models 4105, 5108 and 5120 do not have to be anchored in the floor of the factory or on special measuring tables. They can easily be transported to the required place within a short period. All that is needed at the location is a power connection.

The robust machine housing contains all components of the ATOS ScanBox. As a 100 – 240 V power supply is used and the measuring system only weighs approx. 900 kg, it can be used for measuring in almost all premises. Four wheels enable the unproblematic repositioning of the ATOS ScanBox in the factory shop. The sliding door is designed in such a way that the ATOS ScanBox can be loaded with a crane.

Small geometries, such as locking hooks or catches for injection-molded parts, are often very important for the function. The ATOS ScanBox 4105 can be used with ATOS sensors with the measuring area of 70 × 50 mm2. As a result, it is possible to measure details that are only several tenths of a millimeter in size.

The virtual measuring room is the central control station and measurement planning software for all elements of the ATOS measuring cells. It offers the functional representation of a real measurement environment in a virtual simulation. Thanks to the VMR, the user can work with the system without requiring specific robot programming skills. All robot movements are simulated and checked for safety before being performed in the actual environment.

UCS Tower, plaza # 1, Hill Road Commercial area , phase 6 , Bahria Town, Islamabad Pakistan

The Pakistans leading 3D Printing Service & Marketplace!