What we offer!

Welcome to Ultimate CAD Solutions, the innovation leader in industrial 3D Scanning & 3D Printing

Possibilities

3D Printing

Take control

3D Scanning

ABOUT US

Leading technology company with offices in Pakistan, UAE, Hungary

With the backing of our global partners, professional team and loyal customers, UCS has proven that it can provide quality solutions that match the international standards.

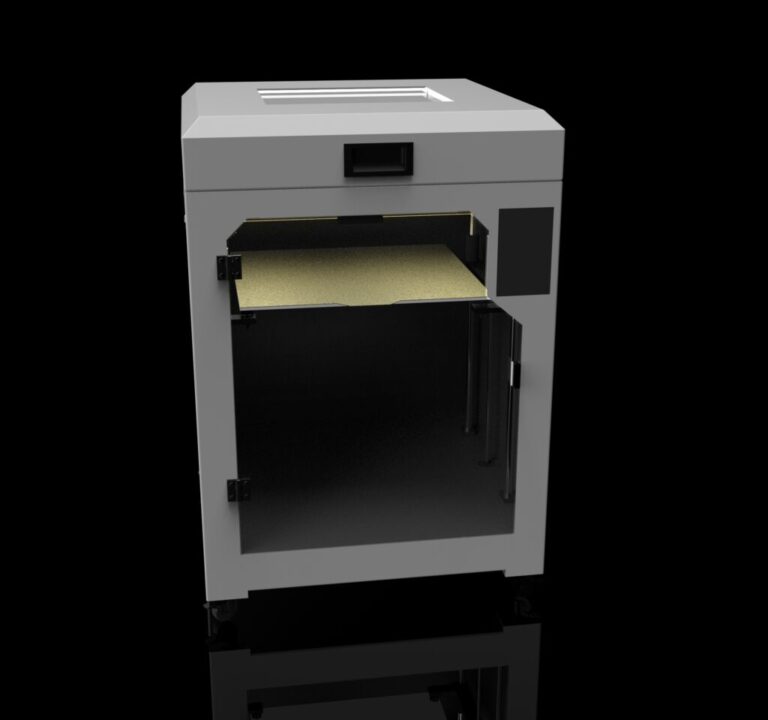

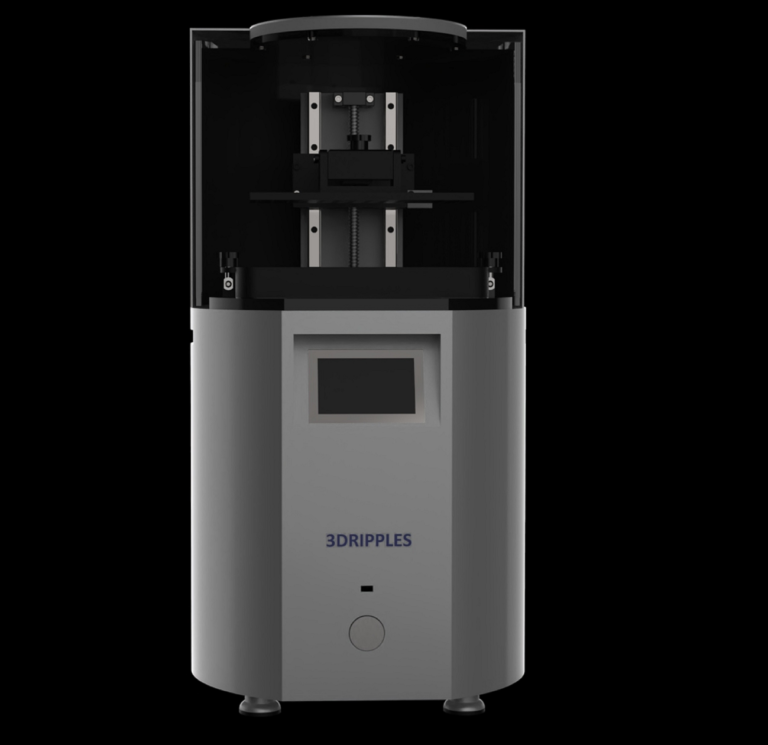

Best Printers

Industrial 3D printer with the speed and reliability to supercharge your production

3D printers help drive your competitive advantage

Make your products faster, cheaper, and more efficiently

Prestigious organizations throughout the country have trusted UCS to implement comprehensive solutions for their challenging problems. We’ve done this by protecting our customer’s investment, improving the efficiency of their operations, and making them more profitable.

Through quality customer service, we have become the nation’s first choice for CAD/CAM/CAE solutions and have formed many long-term relationships with our customers.

Our clients

Driving technology for leading brands

We are trusted by many clients

NOT new in town!

Connected with the Pioneers

We are dedicated to providing our employees a stable work environment with equal opportunity for learning and personal growth. Creativity and innovation are encouraged for improving the effectiveness of Ultimate CAD Solutions (Pvt.) Ltd.

info@ucs-int.com

+92 337 7779040

Location

UCS Tower, plaza # 1, Hill Road Commercial area , phase 6 , Bahria Town, Islamabad Pakistan

About us

The Pakistans leading 3D Printing Service & Marketplace!